Infrared for Construction, Structural, Solar Panel, any structure where residual heat and heat exchange needs to be inspected or monitored.

In the rapidly evolving landscape of construction and building maintenance, the adoption of advanced technologies is not just a trend but a necessity. And with solar energy growing, infrared solar panel array inspections are really the most viable inspection method. One of the most transformative technologies in recent years has been the use of infrared imaging and video, particularly when combined with unmanned aircraft systems (UAS) or drones. This combination is setting new standards for efficiency, safety, and accuracy in roofing, construction, and structural inspections. Eagle Eye UAS Services is at the forefront of this innovation, providing state-of-the-art infrared imaging services that revolutionize how inspections are conducted.

The Power of Infrared Imaging

Infrared imaging technology operates by detecting infrared energy (heat) emitted from objects and converting it into an image known as a thermogram. This image provides a visual representation of the temperature variations of a building’s structure, which are pivotal in identifying problems that are not visible to the naked eye. In the context of construction and roofing, this means being able to pinpoint areas of heat loss, moisture intrusion, and insulation flaws without the need for physical demolition or invasive probing.

Advantages in Construction, Structural, Roofing, and Solar Array Inspections

The integration of infrared technology in construction and roofing inspections offers several distinct advantages:

- Early Detection of Water Intrusion: Infrared imaging can reveal the accumulation of moisture within roof materials and wall cavities, a common precursor to mold growth and structural damage. Early detection allows for timely repairs, preventing extensive damage and reducing repair costs.

- Identification of Insulation Defects: Flaws in insulation can lead to significant energy losses. Thermal imaging provides a clear map of thermal performance across a building, identifying areas where insulation may be missing, damaged, or inadequate.

- Locating Thermal Bridges: These are areas where the heat flows differently than in surrounding areas due to inconsistencies in the material or structural defects. Identifying these bridges is crucial for improving energy efficiency and ensuring the structural integrity of a building.

- Solar Panel Maintenance: Locating dead or dying solar panels and cells in solar panel arrays. With an infrared equipped drone inspection times can be decreased from days to hours. Locating compromised cells and panels can be extremely difficult using standard methods.

- Enhanced Safety: Using drones for infrared inspections significantly enhances safety by reducing the need for personnel to access dangerous or hard-to-reach areas such as high rooftops, tall buildings, and complex industrial structures.

Eagle Eye UAS Services: A Leader in Drone-Based Infrared Inspections

Eagle Eye UAS Services specializes in utilizing drones equipped with high-resolution infrared cameras to conduct detailed inspections of buildings, roofs, solar panel arrays, and other structures. The drones can quickly cover large areas, providing comprehensive data without the logistical challenges and risks associated with traditional inspection methods.

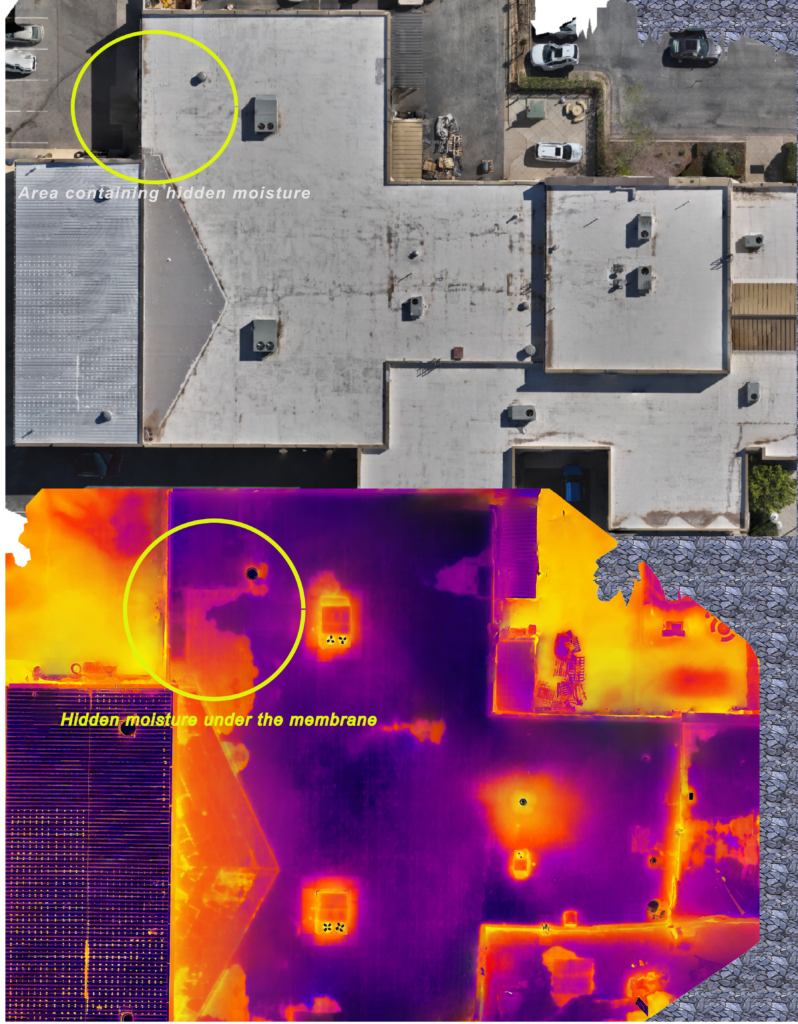

Case Study: A Comprehensive Approach

Consider a recent project undertaken by Eagle Eye UAS Services for a large commercial facility experiencing roof leakage that they just couldn’t locate the source of. Through the deployment of drones equipped with infrared cameras, Eagle Eye was able to identify several areas of roof where there was moisture trapped under the membrane. We discovered where the water was standing and the customer was able to deduce where it was likely coming from based on some recent work they’d had done. Notice also in this IR image that you can identify other heat sources on the roof. Yellow = hottest and Dark Purple = coolest areas. This can be helpful in locating thermal leaks and bridges in structures.

The Process of Infrared Inspection with Drones

The process of conducting an infrared inspection using drones is meticulous and involves several key steps:

- Pre-flight Planning: This involves defining the scope of the inspection, assessing the site conditions, and planning the drone flight path to ensure comprehensive coverage.

- Flight Execution: Drones are flown over the target area, often in a grid pattern to ensure that no section is missed. The infrared cameras capture detailed thermal images that are transmitted in real-time to the inspection team.

- Data Analysis: The thermal images are analyzed using specialized software that interprets the data and highlights areas of concern. This analysis can be integrated with other data sources to provide a holistic view of the structure’s condition.

- Reporting: Eagle Eye UAS Services compiles a detailed report that includes both the infrared images and a professional assessment of the findings. These reports are crucial for maintenance teams and can be used to plan further action or repairs.

Conclusion: The Future of Structural Inspections

The use of infrared imaging and video, especially when combined with drone technology, represents a leap forward in the field of structural inspections. Companies like Eagle Eye UAS Services are leading the way in harnessing these technologies to offer safer, faster, and more accurate inspections than ever before. As these technologies continue to evolve, they will undoubtedly become standard practice in the industry, further enhancing our ability to maintain and improve the built environment efficiently and effectively.

In conclusion, the integration of drone technology with infrared imaging is more than just an enhancement of traditional methods; it’s a complete overhaul that offers profound improvements in how structural health is monitored and maintained. With companies like Eagle Eye UAS Services at the helm, the future of construction and structural inspections is bright, marked by innovation and driven by technology that prioritizes precision, safety, and sustainability.

eeuass@gmail.com

eeuass@gmail.com

Leave a Reply